Improving Protection: Nanotech Meets Mask

Coating Developed by UH Physicist Improves Abilities of Surgical Masks

Seamus Curran never liked playing defense. Mention a problem, and he wants to take charge.

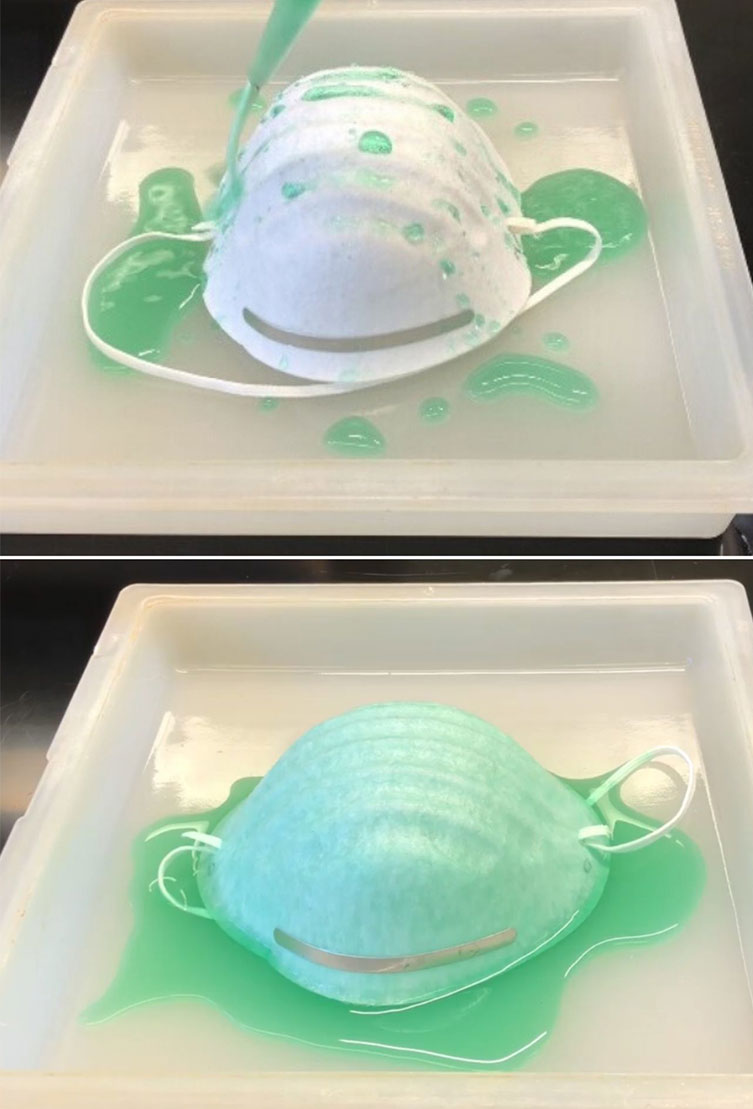

The coronavirus, it turns out, is no different. Curran, a professor of physics at the University of Houston who is well-known for his work commercializing nanotechnologies, is using a hydrophobic coating he developed almost a decade ago to improve the ability of surgical masks to protect against transmission of the virus.

Nanotech Coating Improves Masks

“Standard masks are somewhat porous, and especially if they get wet, they can allow the virus to penetrate,” Curran said, noting that goes both ways — people infected with the virus could spread it even through a mask, while people who aren’t sick could still become infected, despite wearing a mask.

Curran, on the faculty of the College of Natural Sciences and Mathematics, first launched a nanotechnology business in 2013. He currently has a company, Integricote, based at the UH Technology Bridge focused on manufacturing sealers for masonry, wood and concrete. But he has worked with nanotech coatings for fabrics since 2011, technology that he now is using to demonstrate a way to provide more protection against SARS and COVID-19.

Curran has always believed his research should help to address societal problems, and as he learned more about the critical shortage of N95 masks, he wanted to help.

“N95 masks are the gold standard, able to filter very small particles and offering better protection than standard surgical masks,” he said. “But they are hard to manufacture, and global demand is for tens of millions of masks.”

Looking for a Way to Help

“We were seeing the virus spread around the world, and thinking about what we could do,” he said. “I hate playing defense. I wanted to do something.”

He purchased masks in Februrary and began testing his technology. “We can make them impervious to water,” he said. “The solution can improve protection.”

Curran has been talking with investors and manufacturers and said he is ready to ramp up manufacturing capacity.

“We know there is a lot of interest,” he said. “We want to get this out to people as soon as possible.”

Jeannie Kever, University Media Relations